Isibambi seBrashi yeSizilwo saMandla seThermal

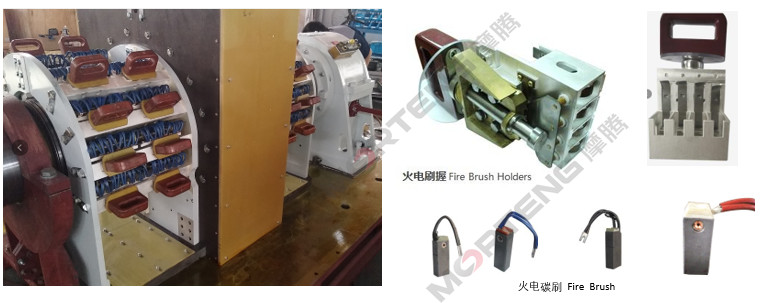

Ingcaciso yeMveliso

1.Ufakelo olufanelekileyo kunye nesakhiwo esithembekileyo.

I-2.Cast i-silicon yobhedu, ukusebenza okuthembekileyo.

Ingcebiso ekhethekileyo

Esi sibambeli sebrashi senzelwe ngokukodwa iseti yejenereyitha ye-injini yomphunga, inokubuyisela ibrashi yekhabhoni ngaphandle kokumisa, efanelekileyo kwaye iyakhawuleza. Uxinzelelo lwebrashi yeCarbon luhlala lusebenza ngokugqwesileyo kokusebenza kwe-buffering. I-Special F class insulated handle igwema ukubamba iindawo eziphilayo ngexesha lokusebenza, ekhuselekileyo kwaye inokuthenjwa.

IiParameters zokucaciswa kobugcisa

| Ibakala lemathiriyeli yomphathi webrashi: ZCuZn16Si4 《GBT 1176-2013 Cast ialloys yobhedu kunye nobhedu》 | |||||

| Ubungakanani bepokotho | A | B | C | D | E |

| MTS254381S023 |

|

|

| ||

Ukwenziwa ngokwezifiso okungengomGangatho kuyakhethwa

Izixhobo kunye nemilinganiselo zinokulungiswa, kwaye ixesha lokuvula ibhrashi eqhelekileyo ziintsuku ezingama-45, ezithatha iinyanga ezimbini zizonke ukucubungula nokuhambisa imveliso egqityiweyo.

Imilinganiselo ethile, imisebenzi, iziteshi kunye neeparamitha ezinxulumene nemveliso ziya kuxhomekeka kwimizobo esayinwe kwaye itywinwe ngamaqela omabini. Ukuba ezi parameters zikhankanywe ngasentla zitshintshiwe ngaphandle kwesaziso kwangaphambili, iNkampani inelungelo lokutolika okokugqibela.

Iingenelo eziphambili:

Isibambi sebrashi esityebileyo sokwenza kunye namava osetyenziso

Uphando oluphezulu kunye nophuhliso kunye nobuchule bokuyila

Iqela leengcaphephe zenkxaso yobugcisa kunye nesicelo, ukuziqhelanisa neemeko ezahlukeneyo zokusebenza ezinzima, ezilungiselelwe ngokweemfuno ezithile zomthengi.

Isisombululo esingcono kunye nesipheleleyo

FAQ

I-1.I-clearance fit phakathi kwesibambi sebrashi kunye ne-carbon brush.

Ukuba umlomo wesikwere ukhulu kakhulu okanye i-carbon brush incinci kakhulu, i-carbon brush iya kujikeleza kwibhokisi ye-brush esebenzayo, eya kubangela ingxaki yokukhanya kunye nokungalingani kwangoku. Ukuba umlomo wesikwere umncinci kakhulu okanye i-carbon brush inkulu kakhulu, i-carbon brush ayikwazi ukufakwa kwibhokisi yebrashi.

2.Umlinganiselo womgama ophakathi.

Ukuba umgama mde kakhulu okanye umfutshane kakhulu, ibrashi yekhabhoni ayikwazi ukugalela embindini webrashi yecarbon, kwaye isenzeko sokutenxa kokusila kuya kwenzeka.

3.Isithuba sofakelo.

Ukuba i-slot yokufakela incinci kakhulu, ngoko ayikwazi ukufakwa.

4.Uxinzelelo oluqhubekayo.

Uxinzelelo okanye ukuxhatshazwa kwentwasahlobo yoxinzelelo oluqhubekayo okanye i-tension spring iphezulu kakhulu, nto leyo ebangela ukuba i-carbon brush igqoke ngokukhawuleza kwaye ubushushu bokudibanisa phakathi kwe-carbon brush kunye ne-torus iphezulu kakhulu.

Imiboniso

Kwiminyaka emininzi, sithatha inxaxheba ngokukhutheleyo kwimiboniso eyahlukeneyo, ukubonisa umthengi iimveliso zethu kunye namandla. Siye sazimasa umboniso eHannover Messe, eJamani; Wind Europe, Wind Energy Hamburg, Awea Wind Power, the USA, China International Cable and Wire Exhibition; Amandla oMoya waseTshayina; njl. Siphinde safumana abathengi abakumgangatho ophezulu kunye nozinzile ngomboniso.

FAQ

1.I-Commutator ikhubazekile--Khulula izikrufu zokubopha ukuze ulungise kwakhona

2. Imihlaba yobhedu okanye imiphetho ebukhali--Re-chamfer

3. Uxinzelelo lwebrashi luncinci kakhulu

3. Lungisa okanye utshintshe uxinzelelo lwasentwasahlobo

Brush overheating

1. Brasha uxinzelelo oluninzi

1. Lungisa okanye utshintshe uxinzelelo lwasentwasahlobo

2. Ukungalingani koxinzelelo lwebrashi enye

2. Ukutshintsha iibrashi zekhabhoni ezahlukeneyo

Nxiba ngokukhawuleza

1. I-Commutator yayimdaka

1. Coca umhambisi

2. Imiphetho ebukhali yobhedu iyabonakala

2. I-Chamfer kwakhona

3. Umthwalo umncinci kakhulu ukwenza ifilimu ye-oxide

3. Phucula umthwalo okanye thabatha inani leebrashi

4.Indawo yokusebenza yome kakhulu okanye imanzi kakhulu

4.Phucula indawo yokusebenza okanye ikhadi lebrashi lokutshintsha