Isibambi seBrashi yeKhabhoni yeRingi yokutyibilika

Ingcaciso yeMveliso

1.Ufakelo olufanelekileyo kunye nesakhiwo esithembekileyo.

I-2.Cast i-silicon yobhedu, ukusebenza okuthembekileyo.

3.Ukusebenzisa i-spring fixed carbon brush, ifom ilula.

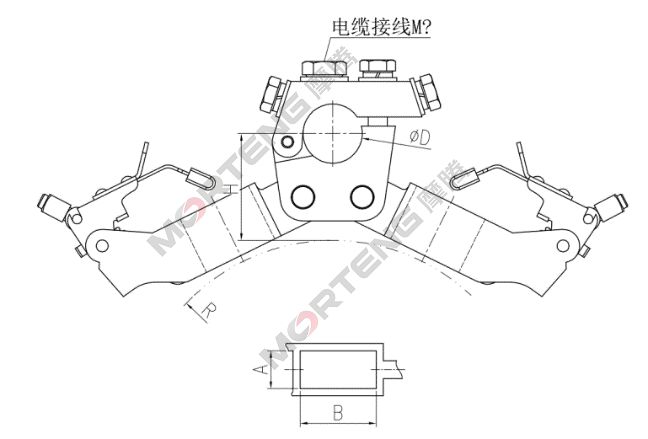

IiParameters zokucaciswa kobugcisa

| Ibakala lemathiriyeli yomphathi webrashi: ZCuZn16Si4 《GBT 1176-2013 Cast ialloys yobhedu kunye nobhedu》 | ||||||

| Ubungakanani bepokotho | A | B | D | H | R | M |

| 5X10 | 5 | 10 | 12 | 20–45 | 20~500 | 4 |

| 8X20 | 8 | 20 | 16 | 20–45 | 30~500 | 6/8 |

| 10X25 | 10 | 25 | 12/16/20 | 20–45 | 30~500 | 6 |

| 12.5X25 | 12.5 | 25 | 25 | 20–45 | 30~500 | 6/8 |

| 12.5X32 | 12.5 | 32 | 16/20 | 20–45 | 80~500 | 8 |

| 16X32 | 16 | 32 | 25 | 20–45 | 80~500 | 10 |

| 20X32 | 20 | 32 | 25 | 20–45 | 80~500 | 10 |

| 25X32 | 25 | 32 | 25 | 20–45 | 80~500 | 10 |

| 20X40 | 20 | 40 | 25 | 20–45 | 80~500 | 10 |

Ukwenziwa ngokwezifiso okungengomGangatho kuyakhethwa

Izixhobo kunye nemilinganiselo zinokulungiswa, kwaye ixesha lokuvula ibhrashi eqhelekileyo ziintsuku ezingama-45, ezithatha iinyanga ezimbini zizonke ukucubungula nokuhambisa imveliso egqityiweyo.

Imilinganiselo ethile, imisebenzi, iziteshi kunye neeparamitha ezinxulumene nemveliso ziya kuxhomekeka kwimizobo esayinwe kwaye itywinwe ngamaqela omabini. Ukuba ezi parameters zikhankanywe ngasentla zitshintshiwe ngaphandle kwesaziso kwangaphambili, iNkampani inelungelo lokutolika okokugqibela.

Iingenelo eziphambili:

Isibambi sebrashi esityebileyo sokwenza kunye namava osetyenziso

Uphando oluphezulu kunye nophuhliso kunye nobuchule bokuyila

Iqela leengcaphephe zenkxaso yobugcisa kunye nesicelo, ukuziqhelanisa neemeko ezahlukeneyo zokusebenza ezinzima, ezilungiselelwe ngokweemfuno ezithile zomthengi.

Isisombululo esingcono kunye nesiphelele

UMorteng unikezela ngoluhlu olubanzi lwabaphethe iibrashi - kuxhomekeke kwisicelo sakho.

Umsebenzi womphathi webrashi kukulungisa iibrashi zekhabhoni kwindawo efanelekileyo. Kukho zonke iintlobo zeentlobo zabanini esinokuthi sizivelise ukuhlangabezana neemfuno ezahlukeneyo nezikhethekileyo.