Isibambi sebhrashi yokuGqala R057-02

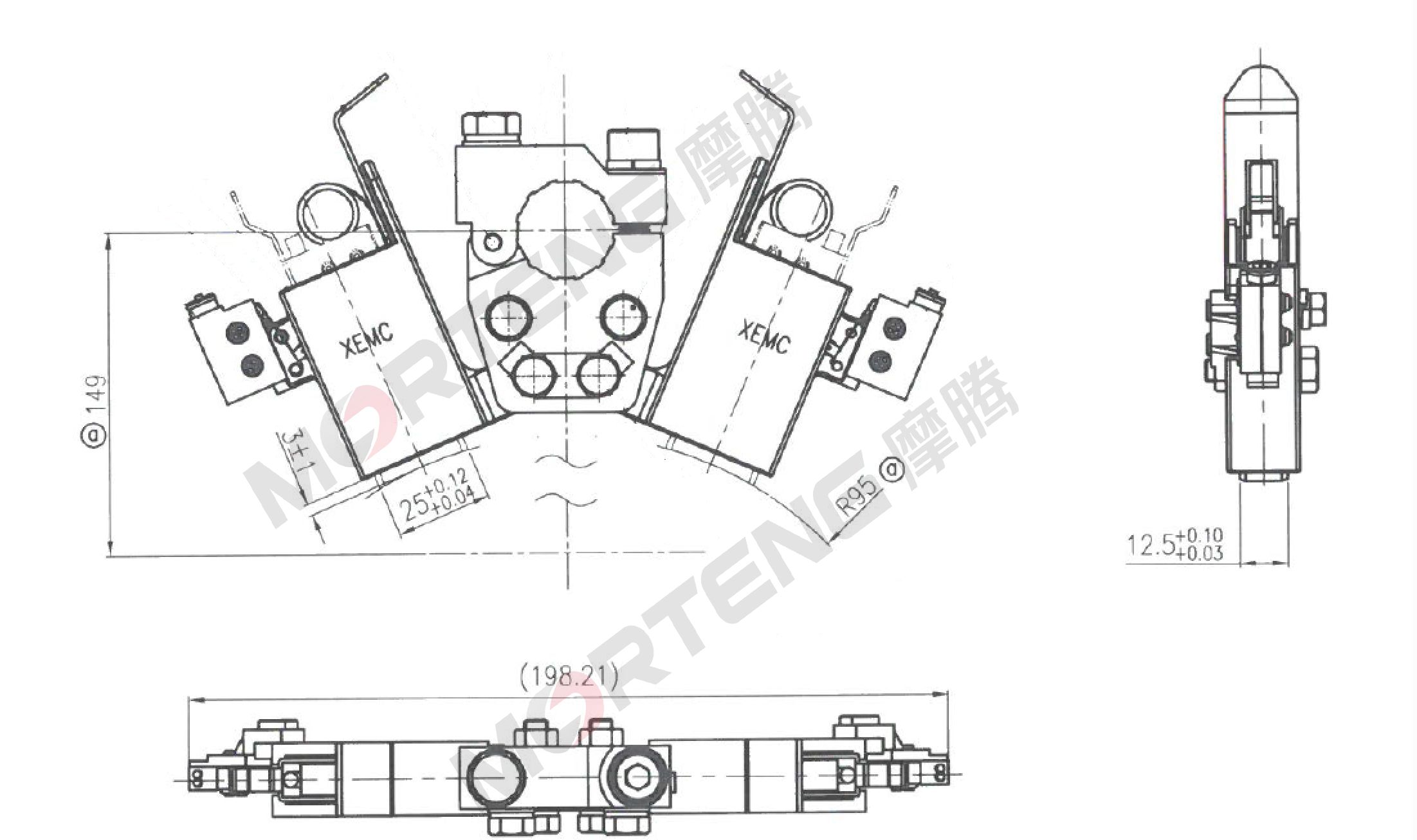

Ingcaciso yeMveliso

| Ibakala lemathiriyeli yomphathi webrashi: ZCuZn16Si4 《GBT 1176-2013 Cast ialloys yobhedu kunye nobhedu》 | |||||

| Ubungakanani bepokotho | Ubungakanani bomngxuma wokunyuka | Umgama weziko lofakelo | Faka isithuba | Idayimitha yangaphandle yeringi ehambelanayo | Ubude boMphathi webrashi |

| 12.5x25 | 25 | 149 | 3±1 | I-R95 | 198.21 |

Uzigcina njani iibrashi zekhabhoni

Isikhokelo kwiingxaki zokugcinwa kwebrashi yekhabhoni

Abathengi abaninzi baya kubuza: Iibrashi zekhabhoni zifuna ukugcinwa njani? Iibrashi zekhabhoni kufuneka zigcinwe ixesha elingakanani? Zifuna ukutshintshwa ixesha elingakanani iibrashi zekhabhoni emva kokusetyenziswa?

Inkcazo eneenkcukacha yeengxaki zokugcinwa kwebrashi yekhabhoni

1. Okokuqala, kufuneka siphuhlise isicwangciso sokulondolozwa kwebrashi ye-carbon

Iibrashi zekhabhoni zinxibe iinxalenye kwizixhobo ze-electromechanical, ekufuneka zitshintshwe kwiinyanga ezi-3-6 phantsi kweemeko eziqhelekileyo. Nangona kunjalo, le yingcebiso yethiyori. Enyanisweni, amaxesha amaninzi, ixesha, kunye nokusingqongileyo kwabasebenzisi abahlukeneyo bebrashi yekhabhoni bahluke kakhulu. Oku kufuna ukuba abasebenzisi bebrashi yekhabhoni benze ukugcinwa rhoqo kweebhrashi zekhabhoni ngokosetyenziso lwabo. Umzekelo, ukuba baqhube ixesha elide, kufuneka bandise Ukuphindaphinda kokugcinwa kwe-carbon brush, njengokuhlolwa kweveki ukujonga isimo se-carbon brush, njl.

2. Okwesibini kukulandela ngokungqongqo isicwangciso solondolozo

Uninzi lwabasebenzisi bebrashi yekhabhoni benze isicwangciso sokulondolozwa kwebrashi yekhabhoni epheleleyo, kodwa abaphunyezwanga ngokungqongqo. Ubunzulu kunye nokuphindaphindwa kokuphunyezwa kwangempela kuncitshiswe kakhulu.

Ngenxa yoko, ubomi benkonzo yebrashi yekhabhoni bufutshane kakhulu, kwaye nomonakalo ongaqhelekanga kwibrashi yekhabhoni okanye umsesane wokuqokelela ubangelwa.

3. Amanqaku okuqwalasela xa ugcina iibrashi zekhabhoni

Okokuqala, kuyimfuneko ukugxila ekugqokeni iibhulashi zekhabhoni kwaye uqinisekise ukuba ukunxiba iibhulashi zekhabhoni akudluli kumgca wobomi. Kwiibrashi zekhabhoni ezingenalo umgca wobomi, phantsi kweemeko eziqhelekileyo, iibhulashi zekhabhoni eziseleyo kufuneka zitshintshwe ngexesha xa ukuphakama kweebhulashi zekhabhoni ezisele ziyi-5-10MM.

Okwesibini, ekugcinweni kweebrashi zekhabhoni, kuyafuneka kwakhona ukuba kugxininiswe ekucoceni i-carbon powder kunye nokungcola kwezinto zangaphandle ukuphepha umonakalo kumphezulu womqokeleli.

Ukongezelela, kuyimfuneko kwakhona ukujonga ukuba ukulungiswa kweebholiti zomphathi webrashi kukhululekile, kwaye ngokuqhelekileyo wenze amanqaku afanelekileyo emva kokugcinwa.

Ekugqibeleni, kukwafuneka ukuba kuqinisekiswe ukuba kukho utshintsho oluphawulekayo kumandla e-elastic entwasahlobo okanye i-elastic force ye-coil ye-spring pressure spring, okanye ukubonakala komonakalo.

4. Isishwankathelo sokugcinwa kwebrashi yekhabhoni

Ukushwankathela, ukuba la manqaku angentla anokufezekiswa, i-carbon brush inokugcinwa kakuhle, engakwazi ukwandisa kuphela ubomi benkonzo ye-carbon brush, kodwa iphinde ikhusele izixhobo ze-electromechanical ezifana nendandatho yomqokeleli kumonakalo. Ukuba abasebenzisi bebrashi yekhabhoni baneminye imibuzo kwinkqubo yokusebenzisa ibrashi yekhabhoni, ungafowunela umnxeba wethu wonxibelelwano nangaliphi na ixesha.

I-Hotline: + 86-21-6917 3552; 6917 2811; 6917, 3550-826