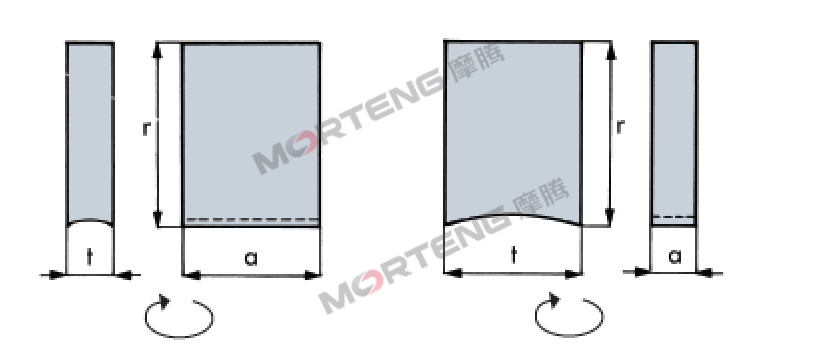

Main Carbon Brush CT53 for GE Suzlon Siemens Nordex turbine

Ingcaciso yeMveliso

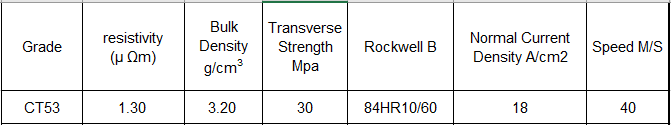

| Uhlobo lwe-Carbon Brush kunye nobukhulu | |||||||

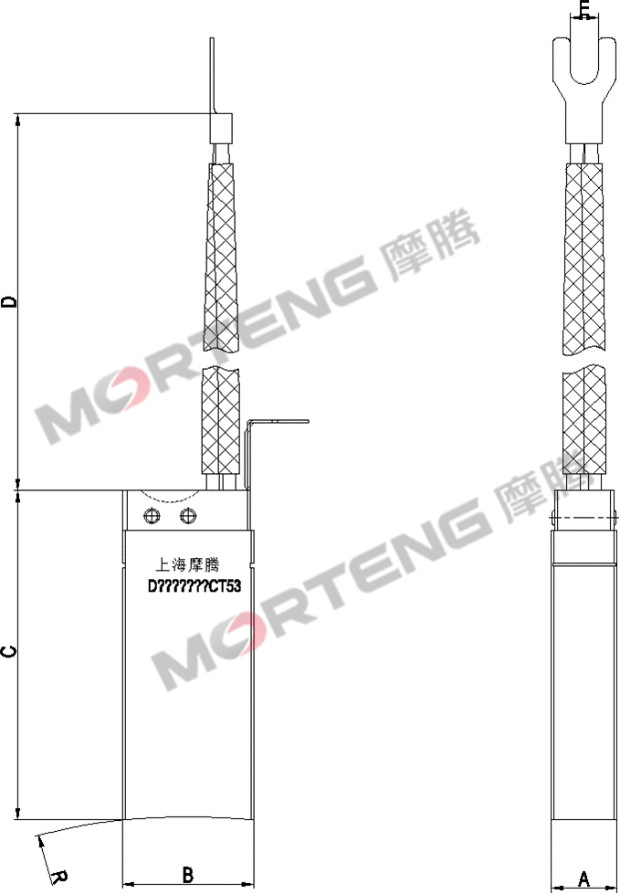

| Umzobo inombolo | IBanga | A | B | C | D | E | R |

| I-MDFD-C200400-138-01 | CT53 | 20 | 40 | 100 | 205 | 8.5 | I-R150 |

| I-MDFD-C200400-138-02 | CT53 | 20 | 40 | 100 | 205 | 8.5 | I-R160 |

| I-MDFD-C200400-141-06 | CT53 | 20 | 40 | 42 | 125 | 6.5 | I-R120 |

| I-MDFD-C200400-142 | CT67 | 20 | 40 | 42 | 100 | 6.5 | I-R120 |

| I-MDFD-C200400-142-08 | CT55 | 20 | 40 | 50 | 140 | 8.5 | I-R130 |

| I-MDFD-C200400-142-10 | CT55 | 20 | 40 | 42 | 120 | 8.5 | I-R160 |

Uyilo kunye nenkonzo elungiselelweyo

Njengomvelisi ohamba phambili weebrashi zekhabhoni zombane kunye neenkqubo zeringi etyibilikayo eTshayina, uMorteng uqokelele itekhnoloji yobuchwephesha kunye namava eenkonzo ezityebileyo. Asikwazi nje ukuvelisa iindawo ezisemgangathweni ezihlangabezana neemfuno zabathengi ngokwemigangatho yelizwe kunye nezoshishino, kodwa sibonelela ngeemveliso kunye neenkonzo ezilungiselelwe ngexesha elifanelekileyo ngokuhambelana neshishini lomthengi kunye neemfuno zesicelo, kunye noyilo kunye nokuveliswa kwemveliso eyanelisayo abathengi. UMorteng unokuhlangabezana ngokupheleleyo neemfuno zabathengi kwaye abonelele abathengi ngesisombululo esigqibeleleyo.

Xa uqhagamshelana nathi ukuze u-odole iibrashi zekhabhoni, nceda unikeze ezi parameters zilandelayo

Imilinganiselo yebrashi yekhabhoni ichazwa njenge "t" x "a" x "r" (i-IEC eqhelekileyo 60136).

• “t” ibhekisa kumlinganiselo wetangential okanye “ukutyeba” kwebrashi yekhabhoni

• "a" ibhekisa kwidimension ye-axial okanye "ububanzi" bebrashi yekhabhoni

• “r” ibhekisa kwidimension yeradial okanye “ubude” bebrashi yekhabhoni

"r" imilinganiselo yeyereferensi kuphela

Imithetho yenkcazo yesayizi yeebrashi zekhabhoni nayo iyasebenza kubahambisi okanye kwi-slip rings.

Nceda unikele ingqalelo kumahluko phakathi kobungakanani bemetric iibhrashi zekhabhoni kunye nobungakanani be-intshi yeebhrashi zekhabhoni, kulula ukubhideka (i-intshi eyi-1 ilingana no-25.4mm, 25.4mm kunye no-25mm)

mm iibrashi zekhabhoni azilingani).

"t", "a" kunye "r" imilinganiselo

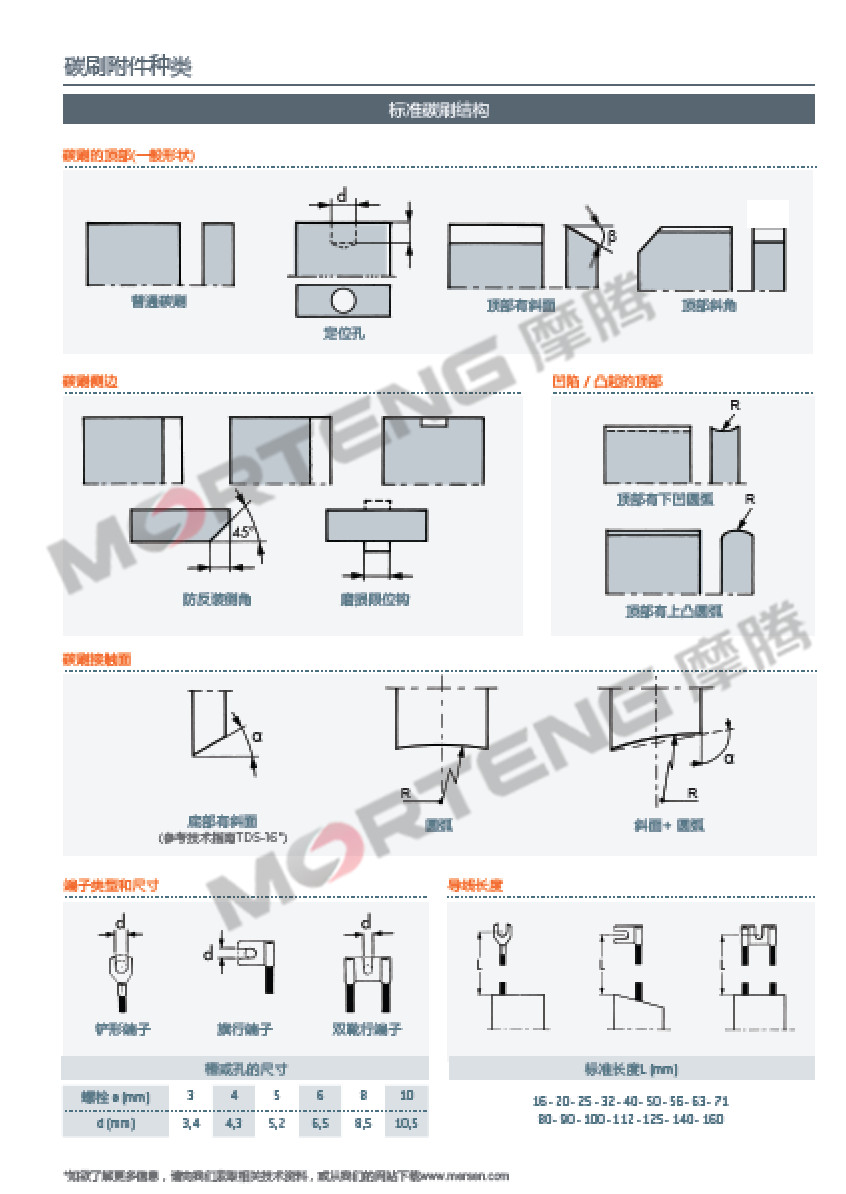

Ulwakhiwo lwebrashi yekhabhoni emilise ngokuyinxenye

Intshayelelo yeNkampani

UMorteng ngumvelisi ohamba phambili womphathi webrashi, ibrashi yekhabhoni kunye nendibano yeringi yokutyibilika kwiminyaka engama-30. Siphuhlisa, siyila kwaye senze izisombululo zobunjineli zizonke kwiinkampani zenkonzo, abasasazi kunye neeOEM. Sinikezela abathengi bethu ngexabiso elikhuphisanayo, umgangatho ophezulu, iimveliso zexesha elikhawulezayo.

Iingcebiso zokufakelwa kweebrashi zekhabhoni

Nazi iingcebiso zethu:

1. Xuba iibhrashi zekhabhoni zezixhobo ezahlukeneyo zemoto enye ngokwestatiki ukuthintela ukusilela okukhulu.

2.Ukutshintsha i-carbon brush material kufuneka uqinisekise ukuba ifilimu ye-oxide ekhoyo isusiwe.

3.Hlola ukuba iibrashi zekhabhoni ziyakwazi ukutyibilika ngokukhululekileyo kwi-brush case ngaphandle kokukhutshwa okugqithisileyo (jonga kwi-Technical Guide TDS-4 *).

4. Khangela ukuqinisekisa ukuba ukuqhelaniswa kweebrashi zekhabhoni kwibhokisi ye-brush kuchanekile, hlawula ingqalelo ekhethekileyo kwiibrashi zekhabhoni kunye ne-bevels phezulu okanye ezantsi, okanye i-segmented carbon brushes kunye ne-gaskets yensimbi phezulu.

Ukusila kwangaphambili komphezulu woqhagamshelwano webrashi yekhabhoni

Ukuze ufanise ngokuchanekileyo i-carbon brush contact surface kunye ne-arc yeringi ye-slip okanye i-commutator, i-carbon brush pre-grinding stone ingasetyenziswa ngesantya esiphantsi okanye akukho mthwalo. I-powder eveliswa yi-grindstone yangaphambili inokwenza ngokukhawuleza i-arc echanekileyo ye-carbon brush contact surface.

Kwakhona kuyimfuneko ukusebenzisa i-grindstone ephakathi emva kokugaya kwangaphambili.

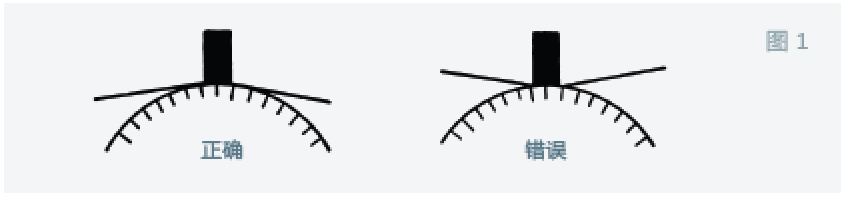

Ukuba ubungakanani bokusila kwangaphambili bukhulu kakhulu, kungcono ukusebenzisa i-60 ~ 80 ye-mesh ye-sandpaper ecolekileyo yokusila ngokurhabaxa. Xa usila rhabaxa, beka i-sandpaper ijonge phezulu phakathi kwebrashi yekhabhoni kunye ne-motor commutator, kwaye emva koko uhambise isandpaper emva naphambili izihlandlo ezininzi, njengoko kubonisiwe kuMfanekiso 1.

Emva kokuba i-carbon brush pre-grinding igqityiwe, indawo yokudibanisa ye-carbon brush kufuneka icocwe kakuhle, kwaye yonke isanti okanye i-carbon powder kufuneka ivuthelwe.