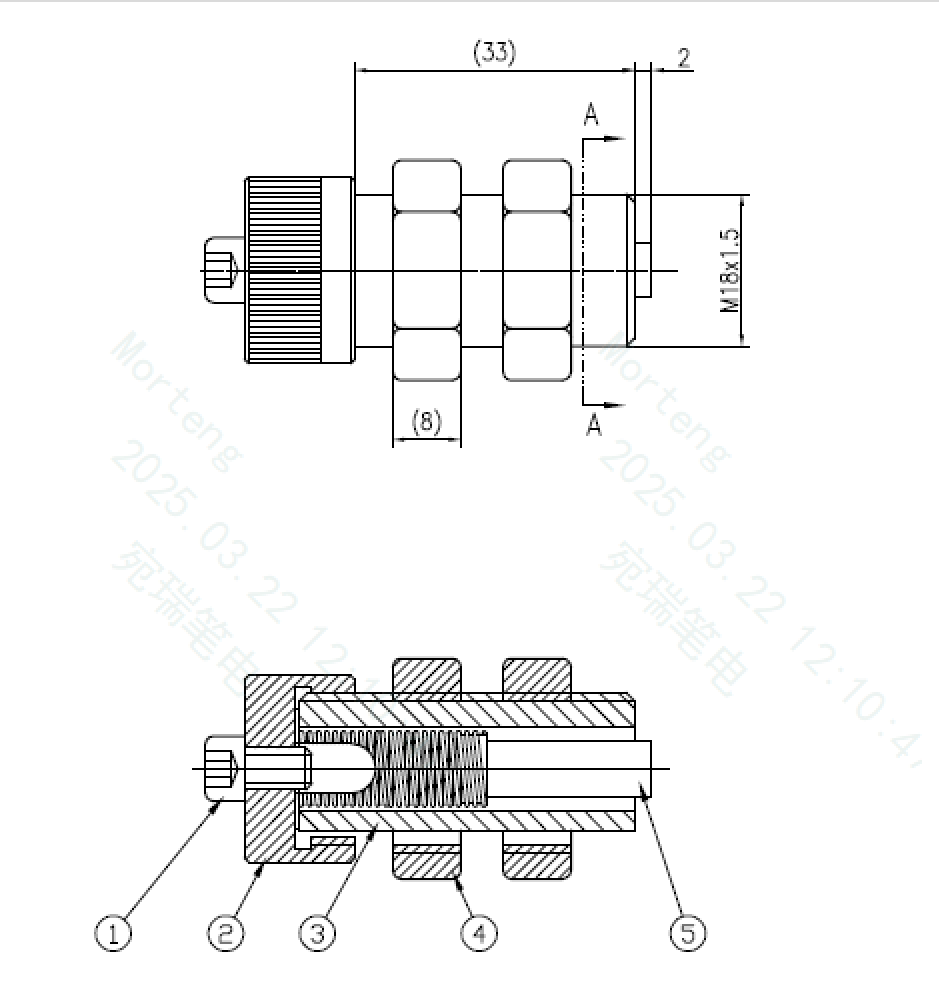

Vestas 753347 iBrash Holder Assembly

Inkcazo eneenkcukacha

Kumaza otshintsho lwamandla ohlaza kwihlabathi, ishishini lamandla omoya, njengenxalenye ebalulekileyo yamandla ahlaziyekayo, lingenisa amathuba ophuhliso angazange abonwe ngaphambili. Nangona kunjalo, ukusebenza ngokufanelekileyo kwezixhobo zamandla omoya akukwazi ukufezekiswa ngaphandle kokuxhaswa kwamacandelo abalulekileyo, phakathi kwawo umnini webrashi, njengenxalenye ephambili yenkqubo yeringi yomqokeleli we-injini yomoya, ichaphazela ngokuthe ngqo ukuzinza kunye nokusebenza kwamandla okuvelisa izixhobo. I-Mortengg, kunye namandla ayo obugcisa ahamba phambili kunye namava atyebileyo kushishino, isungule i-753347 isibambi sebrashi, esifake ubutsha obutsha kwishishini lamandla omoya.

Izibonelelo zobugcisa ze-753347 isibambi sebrashi

I-753347 isibambi sebhrashi yimveliso esebenza ngokuphezulu elungiselelwe ishishini lamandla omoya yiMorteng Technology ngezi nzuzo zilandelayo zobugcisa:

1. Uyilo oluzinzileyo oluphezulu: Ukwamkela i-strut eyodwa e-insulated kunye ne-double-padded cylinder structure ukuqinisekisa ukuzinza komnini webrashi kwindawo ejikelezayo ephezulu kunye nokunciphisa izinga lokungaphumeleli kwezixhobo.

2. Ufakelo olufanelekileyo kunye nokugcinwa: ngokuyila imodyuli kunye nenkqubo yokufakela ukulungelelaniswa, i-753347 umnikazi webrashi unokufakwa ngexesha elifutshane, ukunciphisa kakhulu iindleko zokugcina.

3. Ubomi obude kunye nokusebenza okuphezulu: Ukusetyenziswa kwezinto eziphezulu ze-carbon brush kwandisa ubomi benkonzo kunye nokuphucula ukusebenza kakuhle kokuhanjiswa kwangoku, okunceda ii-injini zomoya ukuvelisa umbane ngokufanelekileyo.

753347 Isicelo seMarike yoMphathi webhrashi kunye neNgxelo yoMthengi

753347 abaphethe iibrashi basetyenziswe ngempumelelo kwiiprojekthi ezininzi zefama yomoya, kwaye impendulo yabathengi ibonisa ukuba:

Izinga lokusilela lincitshiswe kakhulu: ifama yomoya kusetyenziso lwe-753347 isibambi sebrashi, izinga lokusilela kwesixhobo lehle ngama-30%.

Uphuculo lokuvelisa amandla: enye ingxelo yomthengi, ukutshintshwa kwesibambi sebrashi, ukusebenza kakuhle kokuveliswa kwamandla einjini yomoya kunyuke nge-15%.

Ugcino lweendleko zolungiso: Uyilo lweemodyuli lunciphisa ixesha lolondolozo ngama-50% kwaye lunciphisa kakhulu iindleko zabasebenzi.