Umbane wamandla oMbane wokuGwangisa ibhrashi yesiBambi i-MTS160320H037D

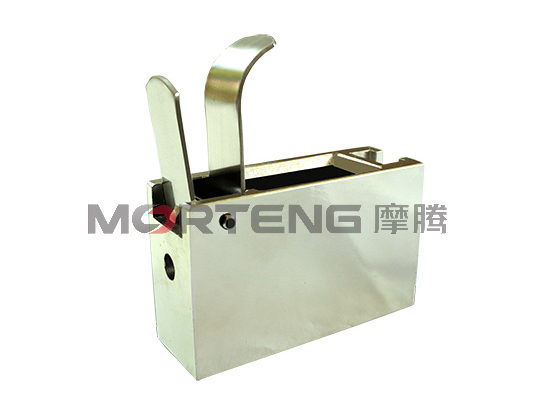

Ingcaciso yeMveliso

1. Ufakelo olulula kunye nesakhiwo esithembekileyo.

2. Yenza izinto zobhedu ze-silicon, ukusebenza okuthembekileyo.

3. I-brush grip nganye ibamba i-carbon brush, enoxinzelelo oluhlengahlengiswayo kwaye isetyenziswe kwi-commutator.

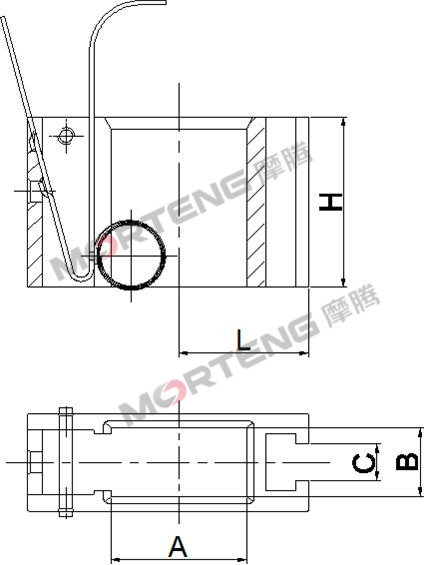

IiParameters zokucaciswa kobugcisa

| Ibakala lemathiriyeli yesibambi sebrashi:ZCuZn16Si4 《GBT 1176-2013 Cast ubhedu kunye nealloyi zobhedu》 | |||||

| Ubungakanani bepokotho | A | B | C | H | L |

| 16*32 | 32 | 16 | 8.5 | 40 | 30.5 |

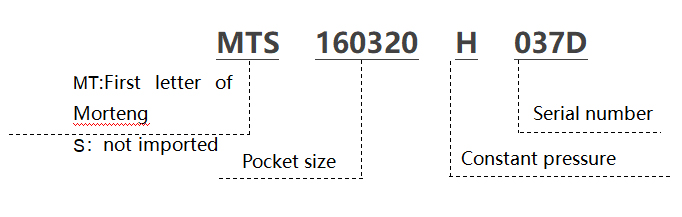

Umyalelo Womyalelo

Ukwenziwa ngokwezifiso okungengomGangatho kuyakhethwa

Izixhobo kunye nemilinganiselo zinokulungiswa, kwaye ixesha lokuvula ibhrashi eqhelekileyo ziintsuku ezingama-45, ezithatha iinyanga ezimbini zizonke ukucubungula nokuhambisa imveliso egqityiweyo.

Imilinganiselo ethile, imisebenzi, iziteshi kunye neeparamitha ezinxulumene nemveliso ziya kuxhomekeka kwimizobo esayinwe kwaye itywinwe ngamaqela omabini. Ukuba ezi parameters zikhankanywe ngasentla zitshintshiwe ngaphandle kwesaziso kwangaphambili, iNkampani inelungelo lokutolika okokugqibela.

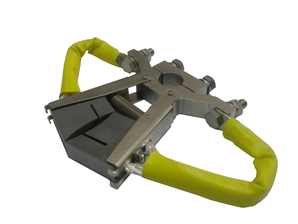

Iingenelo eziphambili:

Isibambi sebrashi esityebileyo sokwenza kunye namava osetyenziso

Uphando oluphezulu kunye nophuhliso kunye nobuchule bokuyila

Iqela leengcaphephe zenkxaso yobugcisa kunye nesicelo, ukuziqhelanisa neemeko ezahlukeneyo zokusebenza ezinzima, ezilungiselelwe ngokweemfuno ezithile zomthengi.

Isisombululo esingcono kunye nesiphelele

Intshayelelo yeNkampani

UMorteng ngumvelisi ohamba phambili womphathi webrashi, ibrashi yekhabhoni kunye nendibano yeringi yokutyibilika kwiminyaka engama-30. Siphuhlisa, siyila kwaye senze izisombululo zobunjineli zizonke kwiinkampani zenkonzo, abasasazi kunye neeOEM. Sinikezela abathengi bethu ngexabiso elikhuphisanayo, umgangatho ophezulu, iimveliso zexesha elikhawulezayo.

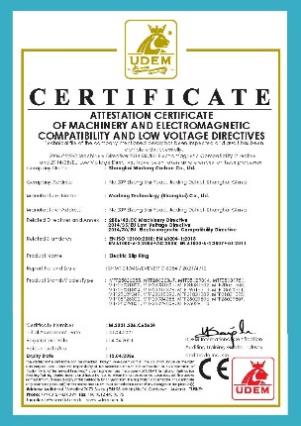

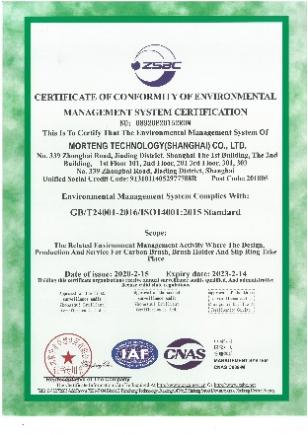

Isatifikethi

FAQ

I-1.I-clearance fit phakathi kwesibambi sebrashi kunye ne-carbon brush

Ukuba umlomo wesikwere ukhulu kakhulu okanye i-carbon brush incinci kakhulu, i-carbon brush iya kujikeleza kwibhokisi ye-brush esebenzayo, eya kubangela ingxaki yokukhanya kunye nokungalingani kwangoku. Ukuba umlomo wesikwere umncinci kakhulu okanye i-carbon brush inkulu kakhulu, i-carbon brush ayikwazi ukufakwa kwibhokisi yebrashi

2.Umlinganiselo womgama ophakathi

Ukuba umgama mde kakhulu okanye umfutshane kakhulu, ibrashi yekhabhoni ayikwazi ukugalela embindini wekhabhoni brashi, kwaye isenzeko sokutenxa kokusila kuya kwenzeka.

3.Isithuba sofakelo

Ukuba i-slot yokufakela incinci kakhulu, ngoko ayikwazi ukufakwa.

4.Uxinzelelo oluqhubekayo

Uxinzelelo okanye uxinzelelo lwentwasahlobo yoxinzelelo oluqhubekayo okanye intwasahlobo yoxinzelelo iphezulu kakhulu, nto leyo ebangela ukuba ibrashi yekhabhoni inxibe ngokukhawuleza kwaye ubushushu bokunxibelelana phakathi kwebrashi yekhabhoni kunye netorus iphezulu kakhulu.

Ukupakishwa